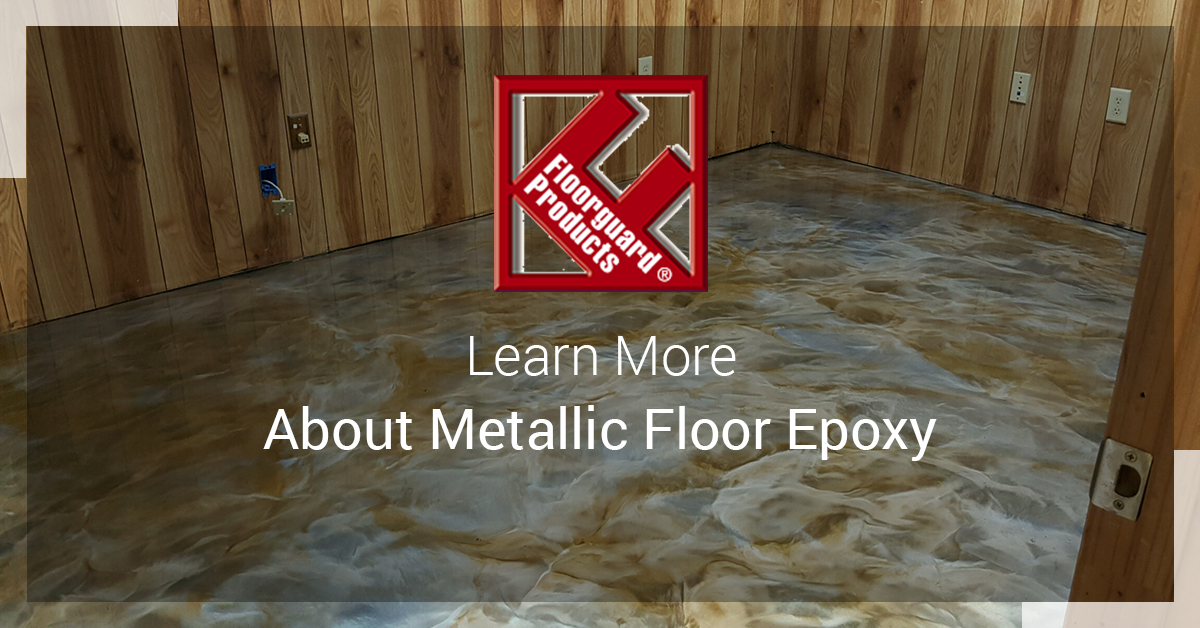

Learn More About Metallic Floor Epoxy

Feb 15th 2018

If you’ve ever set foot in an industrial or commercial setting, you’ve probably walked on epoxy coated floors. Today we would like to discuss epoxy coatings in further detail and even throw in some interesting facts about this material. Are you ready?

What Surface Can You Cover with Epoxy?

Normally, epoxy is used to cover concrete floors to provide a durable, high-performance surface.

How To Prepare Your Floor for an Epoxy Finish

Your concrete floors need to be clean and slightly porous prior to application. If you have any major cracks or chips in the surface of your floor, patch or repair it prior to applying an epoxy coat. Make sure to remove any grease from the surface of your concrete as well.

Test For Prior Sealant

Make sure that epoxy or other sealants are not remaining on the surface of your floor before applying a fresh coat of epoxy. All you need to do is pour water on the floor. If the water soaks in, there is no remaining sealant.

Only Apply Epoxy In Specific Temperatures

Check the manufacturer recommendations to find out what the temperature needs to be during an epoxy application. The last thing you want is for your epoxy coating to bubble and peel.

Application

Once you have mixed your product, you have a certain amount of time to apply the product before it starts to harden. First, apply the primer just like you would with paint and let it dry for a few hours before you coat the floor with epoxy.

Once it’s time to apply the epoxy, cover the floor with a thin layer of water and pour all the epoxy onto the ground. For the next step, you’ll need a roller pin on a pole, which is used to spread a thin layer of epoxy across the floor surface. Once it has dried, apply the second coat.

Fun Facts About Epoxy

Versatile

Epoxy floor coverings are versatile, meaning they can be used on almost all surfaces and not just concrete. You can even use epoxy to coat steel flooring.

Epoxy Resins

Why are epoxy coatings so durable? The answer lies in the epoxy resins present. As the core ingredients in epoxy products, the resins are formulated for the epoxy sealants, top coats and epoxy-based primers. The resins help the coating perform well as a waterproofing layer, protective layer, fire retardant and floor coating.

Works Well With Others

Epoxies can also be mixed with other materials to provide customized floor coatings for different areas. They work well with both alkyds and acrylics.

Durability

Epoxy floors are so durable that they are the preferred choice for industrial plant and factory flooring. These types of floorings are so rugged that they can withstand damage from heavy machinery.

Cross-Linked Molecules

Epoxy resins are truly unique in their composition because of their cross-linked molecules. This makes them extremely resistant to air and water intrusion as well as chemicals and even some corrosive materials.

Excellent Adhesion

Every square inch of epoxy flooring has 1.5 thousand pounds of adhesive power. As a result, epoxy adheres to floors for longer periods of time in comparison to other floor coatings, even when exposed to heavy loads.

Superior Fire Protection

When exposed to heat, certain pigments in epoxy coatings will expand to form a protective layer. This protective barrier lasts until the fire is put out.

Are you looking for epoxy resin floor paint that withstands all kinds of abuse? We have an excellent selection of products to protect your floors. Shop our selection of metallic epoxy floor coatings at Floorguard Products today.